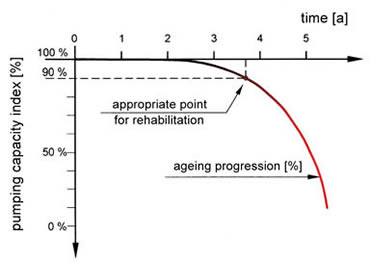

Timing of rehabilitation

As soon as a 10% drop of yield has been observed, a well rehabilitation should be initiated according to the German technical standard DVGW W 130. In most cases this level of decrease in the yield indicates that the well is in an advanced state of precipitating minerals.

A checklist of the required preliminary inspections can be downloaded here.

Comparison of Effectiveness

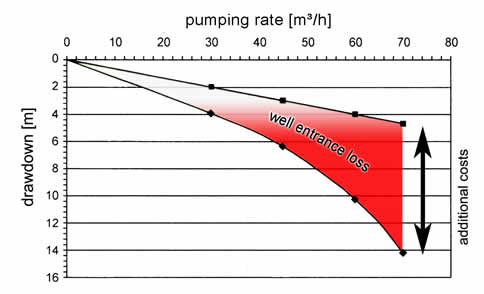

A hydraulic rehabilitation is a fast and cheap cleaning of the well interior including a very limited part of the gravel pack.

Its penetration depth is minimal, however, due to a strong deceleration of cinetic energy in screen slots and gravel pack as the major part of incrustations is located outside the screen pipe.

The more crystalline the incrustations have become and the smaller the pores of the gravel pack have grown over time, the more marginal is the effectiveness of a hydraulic rehabilitation.

A clean well interior is no evidence of a successful rehabilitation, a thorough cleaning of the gravel pack including the annular space is decisive for a good result.

If the surface area of the iron oxide incrustations after the rehabilitation is larger than before it, the oxidisation of the iron increases due to its catalytic efficiency, i.e. the well rehabilitation acts as a catalyst and well ageing will be accelerated instead of stopped.

» Calculate here

» Calculate here » Have fun!

» Have fun!